In the realm of modern lighting and backlighting technologies, Light Guide Plates (LGPs) play a pivotal role in achieving uniform and efficient light distribution. Whether you're working on a commercial lighting project, developing retail shelf backlighting, or designing an indoor light box, selecting the right LGP can make all the difference between a mediocre outcome and a high-performing, visually stunning result. In this comprehensive buyer's guide, we'll walk you through the key factors to consider when choosing an LGP for your specific project.

Before delving into the selection process, it's crucial to understand what LGPs are and why they matter. At their core, LGPs are thin, flat optical components that take light from a light source, typically LEDs, and distribute it evenly across a surface. They are widely used in various applications, including LED backlighting, LED lighting fixtures, signage, and more. The right LGP ensures consistent brightness, minimizes glare, and enhances the overall visual appeal of your project. Conversely, a poorly chosen LGP can lead to uneven lighting, hotspots, and reduced lifespan, ultimately affecting the performance and aesthetic of your end product.

The first step in choosing the right LGP is to clearly define your project's application and use case. Different applications have distinct requirements, and understanding these will guide your selection process.

Lighting Applications: For indoor lighting fixtures, such as ceiling lights or wall sconces, you'll want an LGP that provides a soft, diffused light for a comfortable ambiance. Emergency lighting systems require LGPs that can operate reliably in low-power conditions and provide consistent illumination.

Display Applications: In LED backlighting, LGPs are essential for achieving bright, uniform images. The LGP's thickness, light transmittance, and uniformity rate are critical factors to consider. Digital signage, whether for retail stores, airports, or public spaces, needs LGPs that can deliver high brightness and contrast to ensure visibility from various angles.

The material of the LGP significantly impacts its performance, durability, and cost. The three most common materials used in LGP manufacturing are Poly(methyl methacrylate) (PMMA), Polycarbonate (PC), and Polystyrene (PS).

PMMA (Acrylic): PMMA is a popular choice for LGPs due to its high light transmittance, typically around 92%. It offers excellent optical clarity, good weather resistance, and is relatively cost-effective. PMMA LGPs are commonly used in general lighting, signage, and LED backlighting applications. We recommend and use Mitsubishi PMMA acrylic from Japan.

PC (Polycarbonate): PC LGPs are known for their exceptional impact resistance, making them suitable for applications where durability is a priority, such as automotive, industrial, and outdoor fixtures. They also have better heat tolerance compared to PMMA and can be molded into complex shapes. While PC has a slightly lower light transmittance, around 85 - 90%, advancements in manufacturing techniques have minimized this difference. However, PC LGPs are generally more expensive than PMMA.

PS (Polystyrene): PS is the most cost-effective material for LGPs. It is easy to process and has a relatively high light transmittance of around 80 - 85%. PS LGPs are often used in disposable or low-budget products, such as temporary signage or promotional displays. However, they have poor heat resistance and are less durable compared to PMMA and PC.

In addition to material properties, several technical specifications are crucial when evaluating LGPs.

Light Transmittance: As mentioned earlier, light transmittance is a key factor in determining the brightness of the LGP. A higher transmittance value means more light passes through the plate, resulting in a brighter output. The transmittance is closely related to the dot design in the light guide plate for laser dotting.

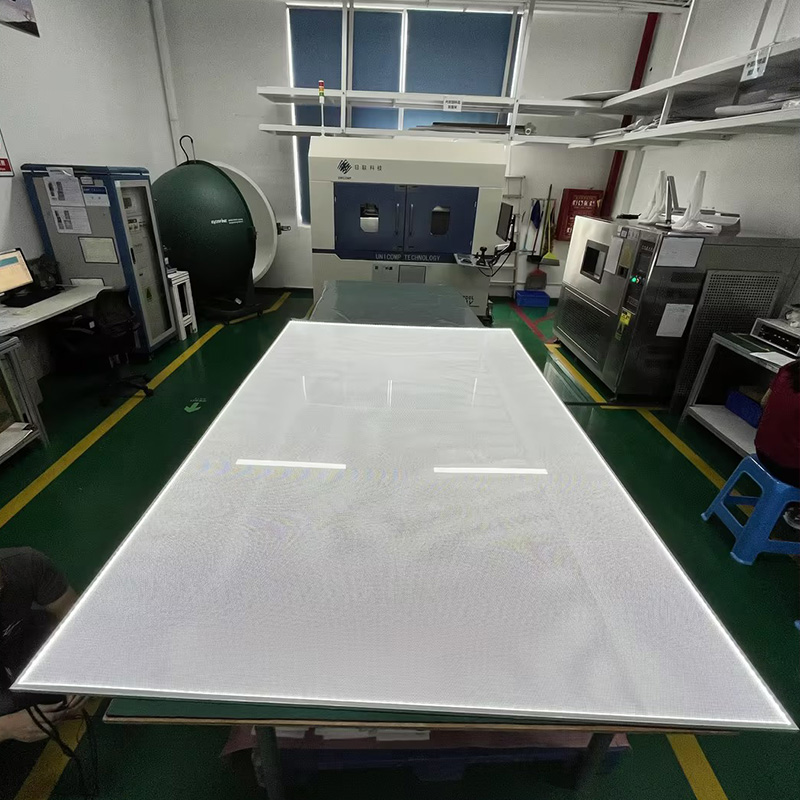

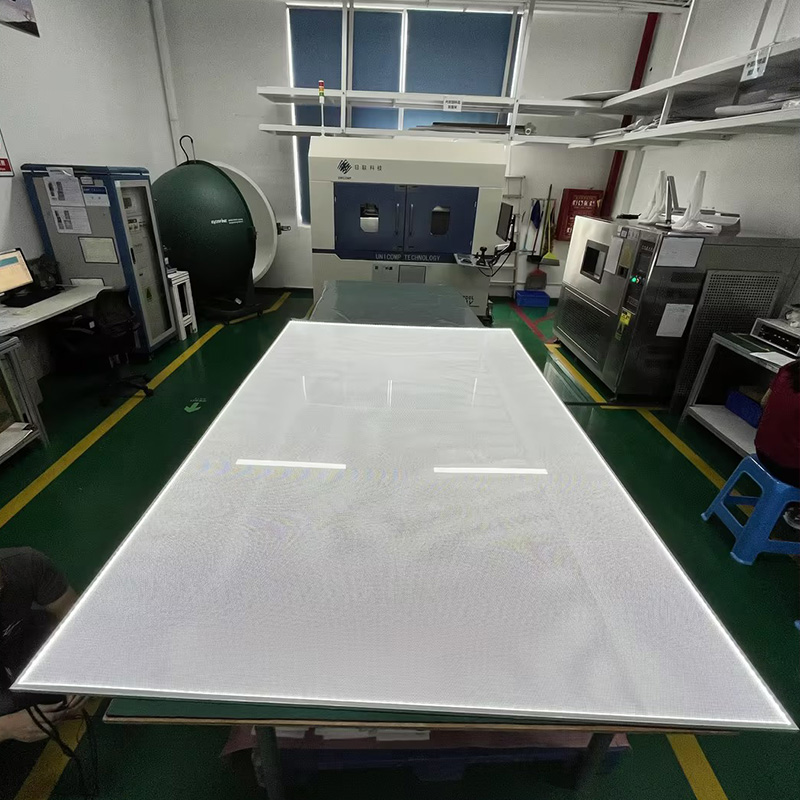

Thickness and Size: The thickness and size of the LGP depend on the application and the available space. Thicker LGPs, between 2 to 10 mm, are suited for larger lighting applications where more light diffusion is required. MAX Size 3000x2000mm is available. Standard LGP sizes are available, such as 300x300 mm or 600x1200 mm, but custom sizes can also be manufactured to fit your specific needs. Keep in mind that custom sizes may come at a higher cost and longer lead time.

Light Uniformity: Light uniformity refers to how evenly the light is distributed across the surface of the LGP. It is typically measured as a percentage, with higher values indicating better uniformity. A good quality LGP should have a uniformity rate of at least 90%. Laser dots offer higher precision and better long-term performance.

The compatibility between the LGP and the light source, usually LEDs, is essential for optimal performance.

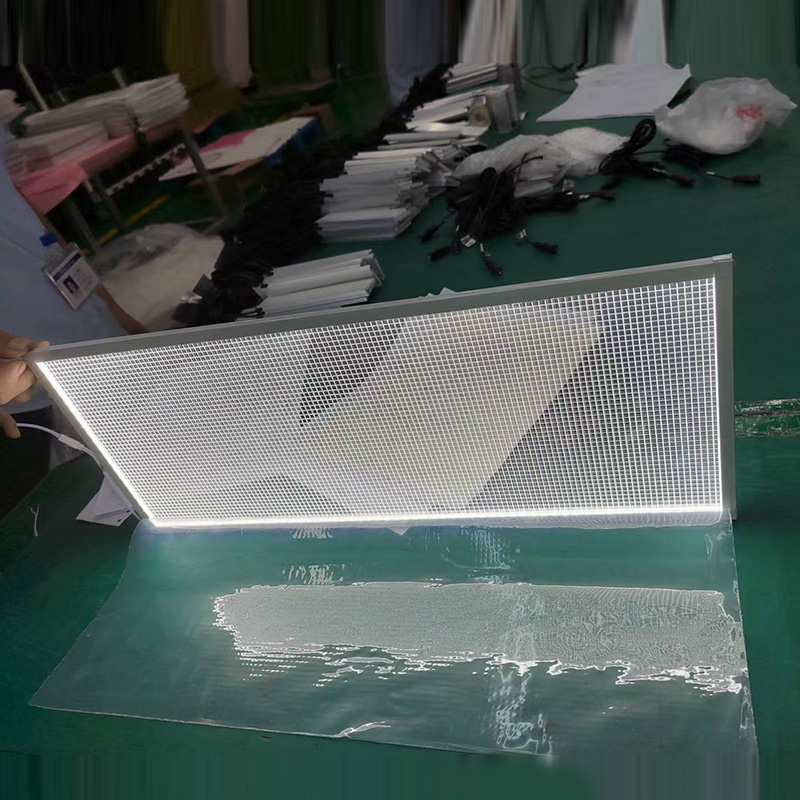

LED Type and Placement: The main types of LGP configurations based on LED placement: edge-lit . Edge-lit LGPs have LEDs positioned along the edges of the plate, and the light is guided through the plate to the surface. This design results in a slim profile, making it suitable for applications where space is limited, such as light box and retail backlighting solution.

Heat Dissipation: LEDs generate heat during operation, and proper heat dissipation is crucial to prevent overheating and extend the lifespan of both the LEDs and the LGP. LGPs used in conjunction with high-power LEDs may require additional heat management solutions, such as heat sinks or thermal conductive materials. Make sure the LGP you select can handle the heat generated by the LEDs and has adequate thermal properties.

The manufacturing process and surface treatment of the LGP can affect its performance, appearance, and durability.

Dot Pattern Technology: As mentioned earlier, the dot pattern on the LGP is responsible for guiding and diffusing the light. There are two main methods of creating dot patterns: engraved and printed. Engraved dots are created by using a laser or mechanical tool to remove material from the surface of the LGP, resulting in a precise and durable pattern. Printed dots, on the other hand, are applied using inkjet or screen printing techniques. While printed dots are more cost-effective for large-scale production, they may be less precise and prone to fading over time.

Surface Finishes: The surface finish of the LGP can enhance its visual appeal and functionality. Matte or anti-glare finishes reduce reflections and glare, making the LGP more suitable for applications where visibility is important, such as eye-friendly lighting fixture,celling light. Glossy finishes, on the other hand, provide a high-brightness and reflective surface, which can be desirable for certain lighting and decorative applications. Additionally, some LGPs may have anti-UV coatings to protect against yellowing, anti-scratch layers for added durability, or anti-static treatments to prevent dust accumulation.

Cost is always a factor when choosing an LGP, but it shouldn't be the sole determining factor. While it may be tempting to opt for the cheapest option, a low-quality LGP can lead to higher long-term costs due to frequent replacements, poor performance, and reduced customer satisfaction. When evaluating the cost of an LGP, consider the following factors:

Material Cost: As discussed earlier, different materials have different costs. PMMA is generally the most cost-effective, followed by PS and PC. However, the cost of the material also depends on factors such as quality, availability, and production volume.

Size and Customization: Larger LGPs and custom sizes typically cost more than standard sizes. Additionally, any customizations, such as complex shapes, precision dot patterns, or special surface treatments, will increase the cost.

Production Volume: Ordering in larger quantities can often result in lower unit costs. If your project requires a significant number of LGPs, consider negotiating with the supplier for volume discounts.

Long-Term Value: While a higher-priced LGP may have a larger upfront cost, it may offer better performance, durability, and energy efficiency in the long run. Consider the total cost of ownership, including maintenance, replacement, and energy consumption, when making your decision.

Now that you're familiar with the key factors to consider when choosing an LGP, here's a step-by-step guide to help you make the right decision for your project:

Define Your Project Requirements: Clearly identify the application, use case, and specific requirements of your project. Consider factors such as the intended use, environmental conditions, desired brightness and uniformity, and any other unique specifications.

Research and Compare Options: Based on your project requirements, research different LGP manufacturers and suppliers. Compare their products in terms of material properties, technical specifications, manufacturing processes, and pricing. Look for reviews, testimonials, and case studies to get an idea of the quality and performance of their LGPs.

Request Samples: Once you've narrowed down your options, request samples from the manufacturers or suppliers. Testing the samples in your actual application will give you a better understanding of how the LGP performs in real

Evaluate Supplier Capabilities: In addition to the quality of the LGPs, it's important to evaluate the capabilities of the supplier. Look for a supplier with a proven track record of reliability, quality control, and customer service. Consider factors such as their production capacity, lead times, technical support, and after-sales service.

Make Your Decision: Based on your research, sample testing, and evaluation of the supplier, make an informed decision and select the LGP that best meets the needs of your project. Don't be afraid to negotiate with the supplier for the best price, terms, and delivery schedule.

When choosing an LGP, it's easy to make mistakes that can have a significant impact on the performance and success of your project. Here are some common mistakes to avoid:

Choosing Based on Price Alone: As mentioned earlier, price should not be the sole determining factor when choosing an LGP. A low-cost LGP may seem like a good deal initially, but it may not meet your performance requirements or have a long lifespan, resulting in higher long-term costs.

Not Testing Samples: Skipping the sample testing process can be a costly mistake. Testing the samples in your actual application will help you identify any potential issues with the LGP's performance, such as uneven lighting or glare, and allow you to make adjustments before committing to a large order.

Overlooking Compatibility: Ensuring compatibility between the LGP and the light source, as well as any other components in your system, is crucial for optimal performance. Make sure to check the specifications and requirements of all components and choose an LGP that is compatible with them.

Choosing the right Light Guide Plate for your project is a critical decision that requires careful consideration of several factors. By understanding the importance of LGPs, evaluating the key factors such as application, material properties, technical specifications, light source compatibility, manufacturing process, and cost, and following the step-by-step selection process, you can make an informed decision and select an LGP that meets the needs of your project. Remember to avoid common mistakes, test samples, and work with a reliable supplier to ensure the success of your project. If you have any questions or need further assistance, don't hesitate to contact our team of experts. We're here to help you choose the perfect LGP for your project and provide you with the support and guidance you need every step of the way.